SR-EM-F Shaft Rings - SR-EM-F-30

Product Description

Axially Assembled, External, ANSI Metric

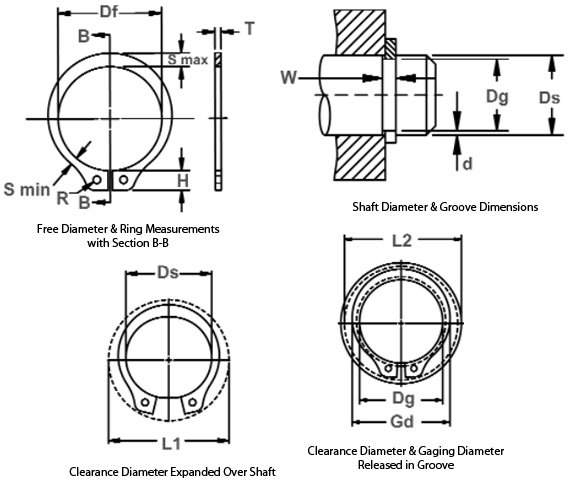

Once installed in the groove of a shaft, the portion of the ring protruding from the groove (also called a “shoulder”) holds an assembly in place.

*F.I.M. (Full Indicator Movement) – Maximum allowable deviation of concentricity between groove and shaft.

Sizes 4 through 6 standard material – carbon steel; optional material – beryllium copper.

For plated rings, add 0.05 to the listed maximum thickness (T) and believed end thickness (U) values.

| Shaft Dia. (mm) Ds | Shaft Dia. (In.) Ds | Groove Depth (d) | Groove Dia. (Dg and Tol.) | Groove Width (W and Tol.) | Ring Free Dia. (Df and Tol.) | Ring Thickness (T and Tol.) | Groove Dia. (F.I.M.*) | Wt. Per 1000 pcs. | Expanded Over Shaft (L1) | Released In Groove (L2) |

|---|---|---|---|---|---|---|---|---|---|---|

| 30 | 1.181 | 0.83 | 28.35 (-0.2) | 1.4 (+0.15) | 27.9 (+0.25/-0.4) | 1.3 (±0.06) | 0.15 | 2.5 | 40.8 | 38.8 |